Pressure washers, or power washers are used for cleaning dirt, stubborn stains, grime and dust from almost all kinds of surfaces including glass, wood, concrete, fiber and steel via high pressure water flow.

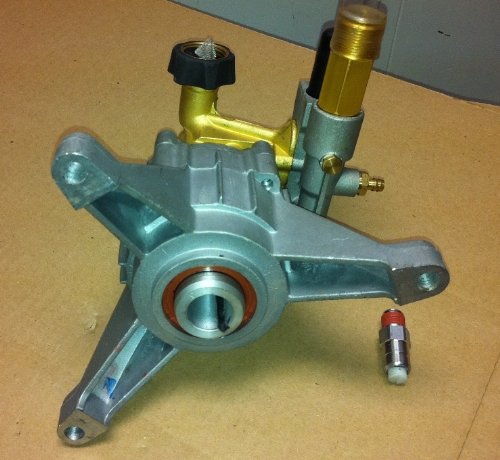

Pressure washers have a lot of parts for effective functioning. The main parts in a pressure washer are the electric or gasoline-powered engine attached to a pump. This pump compresses the water and builds up pressure. The hose has a trigger that has the option of spraying the water either in short bursts or as a continuous spray. The power of the washer depends on the strength of the pump. The nozzle or the tip is also a very important component. This tip can be adjusted at different angels for adjusting the pressure of the water. The smallest angle generates the highest pressure. Larger angles up to 40 degrees are for generating sprays covering larger surface area. Pressure washers also contain a detergent injector that helps to steadily mix the detergent with the water. Other main parts in a pressure washer are the hose, hose reels, valves, heating and cooling components and other plumbing and electrical fittings.

In order to function properly, it is important that all parts are in good working condition. Pressure washers have to be serviced regularly because of the accumulation of dust and grime where they are used. Maintenance involves cleaning the nozzle, which gets clogged with dirt, causing excessive pressure to develop, distorting the spray pattern. Other parts may also develop problems and may have to be replaced from time to time. It is better to consult a hardware technician about pressure washer repair. You can also do a few small repairs and replacements by getting parts from a hardware store. The Internet is a good source of information as well as for buying pressure washer parts. There are several sites that provide useful information about pressure washer repair.